Circular Design isn’t rocket science

I must admit: I am a SpaceX junky. There are very few launches or tests that I miss and quite frequently I bore my family by dragging them upstairs to see yet another Starlink flock of satellites passing over our home. But the best part about those launches, to me, are the landings and reuse of the Falcon 9 booster.

(if you don’t know what I’m talking about, checkout this 40sec. video: https://youtu.be/cbI0U6SItE0)

Some of the Falcon 9 boosters have already flown more than 5 times and they can be reused within a matter of weeks. As little as a decade ago, landing and reusing rockets was unheard of. In fact, even some of the world’s most famous astronauts have stated that SpaceX was not to be taken seriously. This was not how space flight was done… Well, it is now.

THE 9R’S

The benefits of reusing stuff are obvious. If you can reuse a product in its current form, like a secondhand car, or rocket, all you got to do is clean it up and you’re ready to go another round. No new materials are used, very little labor is needed and very little money is wasted.

If you cannot reuse the product in its current form, you can take it apart and still reuse some of the parts in their current form. Let’s take a car that has been in an accident for instance. Maybe it is all beat up and some critical parts might be destroyed, but if the engine is still fine you take that out, reuse it in another car and safe yourself the materials, the work and the waste.

Think about that last line for a minute: “You save yourself the waste”.

That’s right. Cause that waste, nowadays, is your problem. As it should be.

So even if reusing a part is not possible, you could still dismantle the components and recycle the separated materials so they can be used again in new products. This still saves you the cost of the raw materials and it saves the planet from being emptied out.

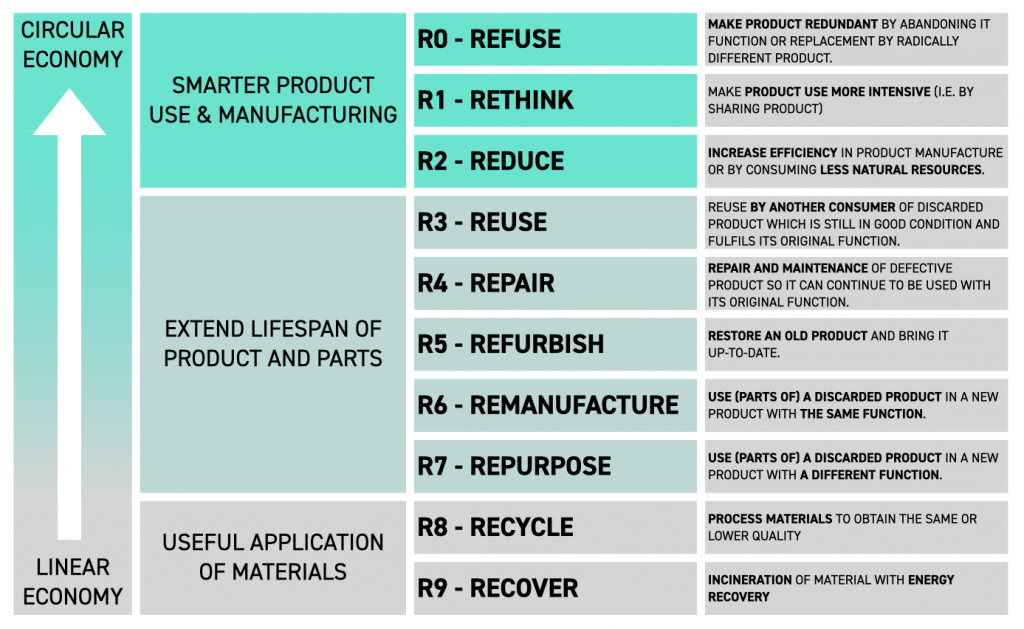

This all sounds pretty logical right? Reusing stuff simply makes sense. And in fact, what I have just described above are a few of the steps in the comprehensive ‘9R Framework for Circularity’: Recover, Recycle, Repurpose, Remanufacture, Refurbish, Repair, Reuse, Reduce , Rethink and Refuse.

For SpaceX, the main drivers behind reusing the Falcon 9 rockets are speed and cost. It means they can get to space on a weekly basis and they don’t waste 35 million per launch by dumping a brand new piece of technology in the ocean. It’s simply good for business, and good for the planet.

IT’S ALL THERE

At Vaan we strongly believe this is the model of the future: where business profits and planet protection are fully aligned with one other. Saving the planet should not be bad for business, and it isn’t. When you design a product to be reused, you will find that is is not hard at all.

When we started the design of the Vaan R4 circular luxury catamaran, we talked to all the usual marine suppliers in the market. They presented us their products in the most fancy ways with sample boxes, factory tours and slick videos. And then our question would be: “Can you leave out all the samples that are not sustainable; meaning not recyclable, not bio based and not certified?” Then something amazing happened…

We were afraid that nothing would be left on the table. That there simply were no sustainable options ready for use in the yacht building sector just yet. But quite the opposite was true: in almost all cases, with almost all suppliers, there were plenty of options left. For interior panels it meant that we could choose from 9 instead of 40 materials. For fabrics it meant that we could select from 10 instead of 100 cloths. And so on. But the big surprise to us was: it’s all there.

Sure, there are some areas where there is no viable sustainable alternative just yet, like sails. And sure, sometimes we really had to dig a bit deeper to find the less commonly used stuff. And yes, people did sometimes frown when they heard about our choices, but we saw that as a good sign. When you break with the past, the past is not going to like you.

SAIL THE PLANET

The Vaan mission is to ‘Sail The Planet’. We make exciting luxury sail yachts that do not harm the planet. By pushing the boundaries of materials, technology and design, we contribute to a world where enjoying life and protecting it, go hand in hand.

We simply care about saving the planet as much as we care about sailing it. Enjoying this beautiful planet should not damage it, right? And it doesn’t have to. Simply reject the options that are not higher up in the 9R framework; the options that you cannot reuse. Pleasure and planet can perfectly coexist.

For us that meant rejecting composites as much as we could. This is why a Vaan is made of recycled aluminium from Hydro. Not only can we recycle the thousands of kilo’s 100% at the end-of-life of a boat, we already use mostly post consumer scrap recycled aluminium. Old window frames, road signs and licence plates are recycled and made into a beautiful sustainable luxury product. And in the process we reduce the energy needed to make the aluminium by 95%. That’s right, 95% energy reduction.

I hope other boat builders will take a close look at their products and business and start rejecting the stuff that is harmful. For every logical choice of the past, there is a new alternative that is in line with the future. Our common future that is. Let’s do this together. This isn’t rocket science. Let’s Sail the Planet.

Igor Kluin

Founder & Designer Vaan Yachts

vaan.yachts